Sim's Electrical Companion

Single Phase Supplies

Single phase supplies have at least two live conductors. Line and Neutral. The line may be any one of the three phase supply conductors. In some cases there may be 2 or more phase conductors of the same phase. This may be to increase the rating of a house by adding another conductor. Another reason for dual conductors may be for continuation of service reasons for example hospital facilities of any other facility that may need a back up in case of power failure. Single phase supplies are common in domestic or light commercial premises.

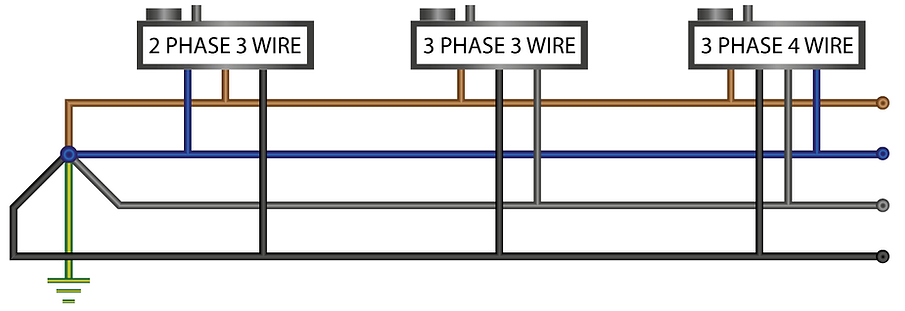

Poly Phase Supplies

Star type supplies that have more than one phase can provide two voltages ratings. Light duty three phase systems have voltage ratings of:

Uo Nominal AC rms value Line to earth: 230V

U Line to Line rms value: 400V

Poly phase systems are used in large domestic, houses of multiple occupancy or flats. Commercial and industrial applications.

3 phase 3 wire would only be used for applications where the loading is balanced e.g. transmission, transformation, distribution systems or balanced three phase loads.

3 phase 4 wire is the most common and most adaptable of the above systems. The neutral can take any imbalances on the phases safely back to the body of earth.

Earthing Arrangements

Identification Labelling and Major Components

Earthing systems are used to protect persons and property against the harmful effects of electrical systems in fault. They provide a path for current to flow to the body of earth and disconnect the supply through ADS (Automatic Disconnection of Supply). Protective devices require current to flow in a complete circuit to operate. The body of earth is often used as a fault path that can be easily referenced from any point in any circuit. There are several types of earthing system they are coded using the following letters:

Earthing Types

T T Terra Terra

The earth connection at suppliers side & an installation earth electrode on the consumers side. The body of earth is used as the protective conductor. Common in agricultural / rural areas remote from public distribution. This method is used as a cheaper method of distribution but must be protected by RCD due to the unstable nature of the earth as a conductor.

I T Impedance Terra

Connected to earth via high impedance resistor on the suppliers side & an installation earth electrode on the consumers side. The body of earth is used as the protective conductor but the current flow in fault conditions is impeded to prevent disconnection of essential services like railway signals or medical locations. This system incorporates an alert feature to warn if the system is in fault.

T N - C Terra Neutral - Combined

The neutral and earth conductors are the same conductor throughout the installation. This is used by suppliers distribution and transmission systems or isolated independent systems. TN-C is rarely used by ordinary consumers but may be employed on a privately owned supply that has no connection to public distribution.

T N - B Terra Neutral - BondedThe neutral and earth are bonded at a pole transformer for example. Give similar results to TN-C-S but can appear to be a TT system. Used in rural areas remote from public distribution. The line neutral is often distributed at high level from the pole transformer. The Earth that has been bonded to the suppliers transformer can be seen running behind a metallic capping to ground on the pole.

T N - S Terra Neutral - Separated

The supply transformer is connected to earth - Terra. Neutral and earthing are separate conductors on the supply and consumer’s side. The most common for of earthing in the UK overall. The system is easily identified by the earthing conductor being supplied by the DNO often the protective armour of the supply cable is used as the earth conductor.

T N - C - S Terra Neural – Combined – Separated

The supply transformer is connected to earth- Terra. Neutral and earth function is combined on the suppliers side. Neutral and earthing are separate conductors on the consumer’s side. This is the most common system in the UK in modern inner city or town areas and is increasing in use replacing TN-S systems.

TT Earthing

T T Terra - Terra Earthing system

The earth connection at suppliers side & an installation earth electrode on the consumers side. The body of earth is used as the protective conductor. Common in agricultural / rural areas remote from public distribution. This method is used as a cheaper method of distribution but must be protected by RCD due to the unstable nature of the earth as a conductor.

In the case of a fault to earth the fault path will flow through the body of earth and return to the protective device to disconnect. It is recommended that TT Systems have additional fault protection for all circuits by means of RCD and supplementary bonding where required. The reason for this is the earth connection Ze can be viable up to 200Ω. To achieve disconnection times the RCD will detect much smaller values than overload protection devices which may not operate in time due to the high resistance of the earth fault loop path.

To find the maximum earth fault loop impedance (Zs) for the RCD we use the 50V rule:

<50V = Safe touch voltage

IΔn = The rated residual current of the RCD protective device

RA = The sum of the resistances of the consumers earthing conductors and earth electrode

A 30mA RCD may have an earth fault loop resistance (Zs) as high as 1667Ω and still operate.

TN-S Earthing

TN - S Terra - Neutral - Separate Earthing system

The most common system in use in populated areas of the UK. This system is being superseded by TN-C-S in inner city / town areas. The earthing system is separate throughout excluding the suppliers connection at the transformer.

This system is recognisable by the earth connection at the consumers end usually being a clamp on the armour of the supply cable and the armour is used as the earth conductor.

The armour may be lead sheath, steel wire armour, aluminium wire armour or even copper cladding on mineral cables. The Earth may be a separate core or separate cable in some cases

.

TN – S system external earth fault loop impedance (Ze) should not exceed 0.8Ω

The mixture of old and harmonised cable colours in the picture right is to demonstrate what you may find.

Line conductor pre <2004: Red, Harmonised colour: Brown

Neutral conductor pre <2004: Black, Harmonised colour: Blue

TN-C-S Earthing

TN - C - S Terra - Neutral - Combined - Separated Earthing system

This System works by using the Neutral as an earth path but in the case that the neutral may be damaged the system will still operate using the PEN (Protective Earth Neutral) conductors as a path to earth similar to TT until the neutral is reinstated. There are normally many PEN conductors along the length of the suppliers neutral cable so it is also given the name Protective Multiple Earthing or PME. TN-C-S Earthing systems external earth fault loop impedance (Zs) should not exceed 0.35Ω

The protective earth and neutral conductor' (PEN) or the 'Combined Neutral & Earth' conductor (CNE) is colour coded to identify its dual purpose. It may be green and yellow with blue sleeving at connections as shown in the above picture or it may be Blue with green and yellow sleeving to identify it.

The illustration shows the main incomer (suppliers cable) the cut out or main fuse and the connection of earth and Neutral at the source of the consumers equipment.

With the cover removed you can see the direct connection of earth and Neutral.

The consumer is not at liberty to connect earth and neutral conductors at any other point in the installation.

* Where the bonding conductor is connected to street furniture and a PME supply.

PME - Protective Multiple Earthing

The Electrical Safety Quality and Continuity Regulations 2002 (ESQCR) prohibit the connection of

PME earthing to any metal work on boats, mobile vehicles, temporary structures, fairgrounds or caravans.

The regulations also prohibit the use of a PEN conductor in medical locations or within a consumers installation.

In most cases construction sites should not be using a PME system unless:

All exposed and extraneous conductive parts are connected to the MET and the additional protection requirements for supplementary equipotential bonding are met. To determine if the connection is effective the resistance of the metallic object to earth should be less than the supply voltage (Uo) divided by the (Ia) current causing the protective device to operate in time.

Ia = IΔn where the protective device is an RCD

Maximum resistance to earth = Ω = R ≤ 50V Uo / Ia (or IΔn)

Specific requirements

Street furniture electrical fixtures the requirements of BS7671 and recommendation G12 state that single phase electric vehicle charging points should NOT be connected to a PME system as it could cause overloading or an imbalance on the supply phase. In agricultural locations PME earthing is not allowed unless a metal grid has been laid in the floor connecting all exposed and extraneous conductors to earth. Exhibitions, shows, stands & mobile or transportable units shall not use PME earthing unless it is within the building or it is under constant supervision of an electrically instructed person and the effectiveness of the earth has been confirmed. This may be done by visual inspection and the use of a loop meter.

TN-C-S with an Outbuilding or Complex

If the TN-C-S building supplied has an outbuilding conditions have been stipulated in the ESQCR regulations that the earth may not be exported in most cases.

To comply with these conditions the distribution cable may not have the earth connected at the main building but may be connected to the consumers own earth rod protecting the outbuilding. Places where this is likely to apply include caravan parks, sheds, workshops & summer houses, marinas, colleges, zoo’s, farms, nurseries and other building complexes that are composed of several structures.

Consumer Earthing

Main Earthing Conductor

In TN systems the main earth is provided by the Distribution Network Operator (DNO). The conductor belongs to the DNO and should not be disconnected when the system is energised & in use. The conductor may be of steel, aluminium or copper construction.

TN-C-S systems will normally be easily identified by the earth connection to the Neutral at the main cut out /fuse block. TN-S systems can be identified by the earth connection being separate throughout its run. Often this connection is made to the steel, lead or aluminium armouring of the supply incoming cable. This equipment belongs to the DNO and should not be tampered with. Faults that are noted s

hould be reported to the DNO. Further information on TN-C-S, TN-S, TT and DNO 's are covered earlier in this chapter.

Selection of the main earthing conductor will have been made by the supplier that originally connected it. Care must be taken if a system is being upgraded to ensure it will still function adequately in fault conditions especially if more power is being drawn. The earthing conductor should be identified but is not always especially in older domestic installations where it may be a steel braid connected to an MET or to the main earth bar of the consumer unit / fuse box.

In TT systems the earthing conductor is the responsibility of the consumer and may consist of rods, tapes, grids or other accepted method. Normally the method of connection to earth is as close as is practicable to the consumer unit. The method is determined mostly by the type of land. For example your not likely to drive a rod into bedrock! Confirmation of a good connection to earth is made with an earth electrode resistance test (this is covered in detail in the testing section of this book). Selection of the earthing conductor is done in one of two ways as specified by BS 7671. It may be selected by use of TABLE 54.7 (below) or by calculation using the adiabatic equation.

Calculation is a more accurate method and especially on large installations can be more profitable as the table is designed to err on the cautious side meaning larger CSA conductors. Cable selection using this method should have a statement to show that the calculation has been performed and allows some room for potential future proofing as the results can be quite surprising how small a cable can survive fault currents for long enough to disconnect. It would be more comforting to know they can survive more than one fault and still be viable.

S Cross sectional area of the protective conductor (mm2)

I Current causing the protective device to operate in time (A)

t Disconnection time (s)

k Temperature coefficient of conductor material

Example:

Using the two methods a final circuit feeding a shower has a BS 60898 B40 circuit breaker. The line conductor is 6mm². According to the table a protective conductor of 6mm² should be used. If the adiabatic equation is used it can be demonstrated that a 1.5mm² cable will carry that fault current for enough time for safe disconnection.*

*Other regulations apply regarding the minimum conductor size & mechanical protection this is just a simple example.

Consumer Protection

Main Bonding Conductors

These connect all conductive parts or services of the building that come into contact with earth. The services include gas, water, oil , structural steel work and any other service that has earth potential. Selection of main bonding conductors is done by selection not less than half the size of the main earthing conductor - usually 10mm² but the minimum size is 6mm² to also ensure mechanical protection. Main bonds to water and gas should be made within 600mm of the gas / water meter or within 600mm of the metallic pipe coming into the property if the meter is outside.

Supplementary Bonding Conductors

Used to bond exposed or extraneous metal work to the Main Earthing Terminal (MET) so in the case of a fault the potential between all exposed metallic parts is the same until the protective device disconnects the fault.

The purpose of all bonding conductors is to bring all conductive pars of the building to the same potential. To avoid dangerous potentials that could cause harm to life, cause damage or fire. Bonding conductors need to be connected using the right equipment. Commonly bolt types, crimps, clamps or connector bars are used. Bonding conductors are colour coded yellow and green. Signage should be used where it is not clear to indicate what service is being bonded. All connections should be accessible and if required their location indicated.

Exposed Conductive Parts

Metallic parts of the electrical installation that should not be live in normal operation. E.g. steel tray, conduit, trunking, metal clad enclosures, consumer units, switch or socket plates, luminaires, pendants, chandeliers etc.

Extraneous Conductive Parts

Metallic parts that are not part of the electrical installation but may become live in case of a fault. E.g. radiators, baths, metallic door or window framing, pipework, metallic stud-work, structural steel, water / gas pipes etc.

In domestic installations most pipe connections are made with a BS 951 clamp with the warning notice:

SAFETY ELECTRICAL CONNECTION DO NOT REMOVE

Gas pipes and water pipes can easily be confused in domestic premises as they may be of the same construction copper or low carbon steel (LCS). Signage or colour coding are used in more commercial applications

(blue for potable water (drinking water) green reclaimed water and yellow for gas). If colour coding is not used labelling is recommended especially at the MET.

Consumer & Supplier Equipment

The installation starts at the incoming cable supplied by the Distribution Network Operator (DNO). As shown on earthing arrangements the supplier may have supplied an earth cable in the case of TN systems or the consumer is responsible for providing their own earth in the case of TT systems.

1 Cut Out

The cut out is the first connection made by the supplier DNO often called the supply head or Henley block. The phase or line conductors should be fused to protect the suppliers cable. The neutral should NOT be fused as was practiced up until the mid 1950's. If you find a fused neutral it is free to be upgraded by the DNO and it is their responsibility to do so. The line or phase fuses will be high breaking capacity fuses normally to BS 88 or BS 1361.

2 Meter

The next connection is to a meter single or three phase depending upon the supply type. The meter will record consumed energy and will be logged for the consumer to pay. In some cases there may be two readings on the meter where more than one tariff may be used peak & off peak. There may also be a separate cogeneration meter if the installation has a method of generating its own electricity e.g. Photovoltaic or wind turbine.

3 Meter Tails

In domestic or light commercial they are commonly 16mm² or 25mm². 16mm² cable is designed for a current carrying capacity of a maximum of 85A in perfect conditions so if it is protected by a 100A cut out this should be down rated to 60A or 80A to protect the cable.

4 Earthing Conductors

The connection from the suppliers cable on TN systems is the suppliers EARTH. For TT earthing systems the consumer provides the earthing conductor.

5 Main Earthing Terminal

This can be a bar in the consumer unit / fuse-board or a separate terminal block to connect the main earth, consumer earth and main bonding conductors. These should be labelled to indicate their purpose.

6 Consumer Tails

These should be the same size or larger than the meter tails. For modern domestic installations, it is recommended to fit 25mm² even if the supply is 16mm² in case the DNO upgrades the installation at a later date.

To safely install the consumer tails it is necessary to safely isolate the supply. Three methods of isolation include:

1) Remove the suppliers fuse (with permission from the DNO to remove the security tag)

2) Use an isolator if one is installed between the meter and the consumer unit

3) Modern meters have an isolator switch built into them to allow safe isolation.

7 Consumers Earth: Should be the same csa as the suppliers earth or greater.

Consumer & Supplier Equipment

Pre 1950's

Fuses were fixed to a wooden board and connected with braided cables. BS 1361 cartridge fuses for domestic single phase installations <100A were introduced in 1947. Hopefully any fuse-boards installed before the 1950's are supervised, in a museum or not in service.

1950-1960

Mostly constructed from brown Bakelite plastic mounted onto a wooden back plate. Protection was in the form of rewireable semi enclosed fuses to BS 3036 are installed from 1958. Often only had 2-4 ways as most domestic properties only had a few circuits. It was common to have one power, one lighting and either cooker or heating.

1960-1970

White / cream plastic was commonly used or a Grey enamel coated metal casing. Fuses started to be replaced with circuit breakers although rewireable fuses were still in common use. The first standard of circuit breakers were introduced in 1965 to BS 3871 Push button or toggle switches improved the safety and speed of reinstating overloaded circuits.

Main switches introduced in 1977 to the standard of BS 5419. White cream plastic and grey metal was still the most common form of consumer unit with complete boxing in front back and sides. In some cases this was a modular metal enclosure with adaptable outlets.

1980-1990

PVC plastic enclosures were common place and Residual Current Devices (RCD's) to BS 4293-1983 were introduced to protect against earth leakage in low voltage installations. More ways on consumer units allow for greater selectivity and less disruption to healthy circuits in fault conditions.

1990-2000

The recent standard of BS 60898 circuit breakers was being adopted in 1992 and phasing out of the older standards on new installations of the time. Main switch isolators to BS 60947-3 were adopted replacing the previous accepted standards. RCD's becoming more common and a new standard BS 61008-1 with a two module format was adopted for multiple circuit protection in 1995. RCBO's providing earth fault and overload protection in a two module or single module format introduced to the standard BS 61009 in 1995.

2015

17th Edition Amendment 3 of BS 7671 Requirements for Electrical Installations made it regulation to install non-flame propagating materials for domestic consumer units.

The increased used of split load or high integrity boards was becoming commonplace to avoid nuisance interruption of services sharing RCD's. Installations started to make use of RCBO's to allow more selectivity regarding earth faults.

2018

New installations now have additional surge protection devices unless a risk assessment has been performed. Additional arc fault protection is recommended for use in locations with increased risk of fire or with sleeping accommodation.

Introduction of Arc Fault detection devices for HMO's, care homes and blocks of flats above 6 stories. Notices no longer required at or near the consumer unit, they can be part of a pack.

2022

Introduction of Arc Fault detection devices for installations where additional danger is present. Higher Risk Residential Buildings (HRRB) House in Multiple Occupation (HMO) Purpose-built student accommodation.